A Clean, Green Way to Recycle Solar Panels

Inside a shipping container in an industrial area of Venice, the Italian startup 9-Tech is taking a crack at a looming global problem: how to responsibly recycle the 54 million to 160 million tonnes of solar modules that are expected to reach the end of their productive lives by 2050. Recovering the materials won’t be easy. Solar panels are built to withstand any environment on Earth for 20 to 30 years, and even after sitting in the sun for three decades, the hardware is difficult to dismantle. In fact, most recycling facilities trash the silicon, silver, and copper—the most valuable but least accessible materials in old solar panels—and recover only the aluminum frames and glass panes.

The startup 9-Tech operates its pilot plant out of a modified shipping container housed at the Green Propulsion Laboratory in the industrial port of Marghera in Venice.Luigi Avantaggiato

The startup 9-Tech operates its pilot plant out of a modified shipping container housed at the Green Propulsion Laboratory in the industrial port of Marghera in Venice.Luigi Avantaggiato

The need for recycling will only grow as the world increasingly deploys solar power. More than 1.2 terawatts of solar power has already been deployed globally. Solar panels are currently being distributed at a rate of more than 400 gigawatts per year, and the rate is expected to increase to a whopping 3 TW per year by 2030, according to a literature analysis by researchers at the National Renewable Energy Laboratory (NREL).

In an attempt to stop a mountain of photovoltaic garbage from accumulating, researchers are pursuing better recycling methods. The most advanced methods proposed so far can recover at least 90 percent of the copper, silver, silicon, glass, and aluminum in a crystalline silicon PV module. But these processes are expensive and often involve toxic chemicals. No recycling method has proven to be as cheap as landfilling, and very few operate on an industrial scale, says Garvin Heath, principal environmental engineer at NREL, who manages a group of international experts assigned by the International Energy Agency to analyze PV sustainability.

The founders of 9-Tech say they have a better way. Their process is a noisy one involving a combustion furnace, an ultrasound bath, and mechanical sorting, the vibrations of which shake the floor of the modest freight container where they have been testing their operation for nearly two years. The company uses no toxic chemicals, releases no pollutants into the environment, and recovers up to 90 percent of the materials in a solar panel, says Francesco Miserocchi, chief technology officer at 9-Tech.

![]() Bits of silicon and glass are separated from the rest of the panel.

Luigi Avantaggiato

Bits of silicon and glass are separated from the rest of the panel.

Luigi Avantaggiato

How to Recycle Solar Panels

After the frame, glass, and junction box are removed from a PV panel, the inner, bendable layers of silicon, polymers, and metal conductors remain. Workers cut the inner layers into large sections in preparation for the oven.Luigi Avantaggiato

After the frame, glass, and junction box are removed from a PV panel, the inner, bendable layers of silicon, polymers, and metal conductors remain. Workers cut the inner layers into large sections in preparation for the oven.Luigi Avantaggiato

The company tailors its process to crystalline silicon solar panels, which make up 97 percent of the global PV market. The panels typically consist of an array of silicon wafers doped with boron and phosphorus, and topped with an antireflective coating of silicon nitride. Silver conductors are screen printed onto the wafer surface, and copper conductors are soldered onto the array in a grid pattern. To protect the materials from moisture and damage, manufacturers laminate the entire array in adhesive polymers—usually ethylene-vinyl acetate. Then they encase the laminated array in sheets of tempered glass, frame the whole thing in aluminum, seal the edges, and attach a junction box on the back.

When it’s time to recycle a panel, one of the most challenging steps is removing the polymers, which stick to everything. “It’s not just the edges or a couple of dots of glue. It’s an entire surface—several square feet—of polymer,” says Heath. The polymer can be burned off, but this releases carbon monoxide, hydrofluoric acid, and other harmful pollutants. Separating the silver conductors also proves challenging because they’re applied in a very thin layer–about 10 to 20 micrometers–that is strongly attached to the silicon. Removing them typically involves toxic reagents such as hydrofluoric acid, nitric acid, or sodium hydroxide.

The team at 9-Tech addresses these challenges in two ways. They recover the silver using ultrasound rather than toxic chemicals, and although they burn the polymers, they capture the pollutants emitted.

Layers of silicon and polymer are fed into a continuous combustion furnace, which heats the materials to over 400 °C, vaporizing the polymers. 9-Tech

The process at the company’s pilot plant starts with workers manually removing the aluminum frame, junction box, and tempered glass. This leaves a sandwich of polymers, silicon wafers, and metal conductors. Without the frame or glass, the sandwich layers bend, shattering the fragile silicon into small pieces. Workers crack the tempered glass and then send all the materials, which are mostly still in place because of the polymers, into a continuous combustion furnace. Heated to over 400 °C, the polymers vaporize, and a filter captures the pollutants. The system also captures the heat from the furnace and reuses it for energy efficiency.

A mechanical roller separates the copper grid after the PV materials exit the furnace.Luigi Avantaggiato

A mechanical roller separates the copper grid after the PV materials exit the furnace.Luigi Avantaggiato

![]() After the materials exit the oven, mechanical sieves separate the copper, glass, and silicon.

Top: Luigi Avantaggiato; Bottom: 9-Tech

After the materials exit the oven, mechanical sieves separate the copper, glass, and silicon.

Top: Luigi Avantaggiato; Bottom: 9-Tech

As the remaining material exits the furnace, a roller mechanically strips out the copper. A series of sieves sort the broken bits of glass and silicon based on thickness. The silicon pieces, still laced with silver, are immersed in a bath of organic acid and treated with ultrasound to loosen the bonds between the elements. The ultrasound works by propagating sound waves into the acid bath, resulting in alternating high- and low-pressure cycles. If the waves are intense enough, they create cavitation bubbles that mechanically interact with the material, causing the silver to dislodge from the silicon, explains Pietrogiovanni Cerchier, CEO at 9-Tech.

Finally, workers remove the silicon fragments from the ultrasound bath with a mesh net. This leaves a fine silver dust in the solution, which can be recovered by filtration or centrifuge. All told, Cerchier says, 9-Tech’s pilot plant can recover 90 percent of the silver, 95 percent of the silicon, and 99 percent or more of the copper, aluminum, and glass from a PV module. What’s more, the material is considered highly pure, which increases the types of applications for which it can be reused.

Workers at 9-Tech immerse silver-laced silicon pieces in a bath of organic acid and treat it with ultrasound to loosen the bonds between the elements. 9-Tech

The startup’s recycling process is more expensive than existing methods that recover only aluminum and glass. But the extraction of high-purity silicon, silver, and copper should offset the extra cost, Miserocchi says. Plus, it’s more efficient than mining for virgin elements. You can extract about 500 grams of silver from a tonne of solar panels, but only 165 grams of silver from a tonne of ore, he says. “A photovoltaic panel at the end of its life still has a lot to give,” says Miserocchi. “It can be considered a small mine of precious elements.”

Silver emerges from the silicon bath in a fine dust. 9-Tech

Silver emerges from the silicon bath in a fine dust. 9-Tech

Dozens of New Ways to Recycle PV Panels

![]() High-purity copper, glass, and silicon are recovered from 9-Tech’s PV-panel recycling process.Luigi Avantaggiato

High-purity copper, glass, and silicon are recovered from 9-Tech’s PV-panel recycling process.Luigi Avantaggiato

The 9-Tech team will know more about the profitability of their method after they build a larger demonstration facility over the next 18 months. That plant, to be located in the same industrial district of Venice as the shipping container, will be able to handle up to 800 solar modules a day. Their pilot plant processes only about seven modules a day.

The company’s approach is one of many recycling methods for crystalline silicon PV panels in development. A comprehensive review published in April in the Journal of Cleaner Production identified dozens of other efforts globally, including thermal, chemical, mechanical, and optical approaches. The most common method involves grinding the silicon, metal, and polymer layers into small pieces, separating them by density, and recovering the silicon and metal with a thermal or chemical process. Other processes include laser irradiation, high-voltage pulses, optical sorting, pyrolysis, chemical solvents, etching, and delaminating with a hot knife.

Driving this innovation, in part, are regulations adopted by the European Union in 2012. The rules require all PV panel manufacturers in the EU to run take-back or recycling programs, or partner with other recycling schemes. As a result, Germany, which has the most solar power capacity in Europe, has one of the largest PV recycling systems in the world.

“A photovoltaic panel at the end of its life still has a lot to give,” says Miserocchi. “It can be considered a small mine of precious elements.”

But recycling is a high-volume business, and aside from catastrophic weather events that wipe out solar power stations, spent solar modules reach recyclers at a relative trickle. And then there’s the challenge of finding a second life for the materials after they are recovered—a supply chain that’s not well developed.

First Solar, a global PV manufacturer based in Tempe, Ariz., addressed both of these issues on a large scale by building an in-house recycling program with seven facilities in five countries. The company makes cadmium telluride thin-film solar panels that buyers can purchase with the recycling price built in. At the end of the panels’ lives, buyers send them back to First Solar for recycling into new products. The semiconductor material can be recycled up to 41 times, giving it a life-span of more than 1,200 years, according to the company. But the glass isn’t pure enough to be reused in solar modules, so the company plans to supply it to float-glass manufacturers for use in windows and doors.

The challenges with recycling have inspired researchers to rethink the way crystalline solar panels are made. For example, some manufacturers are trying to reduce or eliminate the difficult-to-recover silver, replacing it with other conductive metals. And a team at NREL demonstrated in February a way to eliminate polymers in PV panels by laser welding the glass panes instead, which may do a better job sealing out moisture. That technique may lend itself to perovskite solar modules, a promising technology that is particularly susceptible to moisture and corrosion.

“Recycling shouldn’t be the only strategy,” says Heath. People should consider alternative ways to repair or reuse solar panels to extend their lives before resorting to recycling, he says.

Additional reporting by Luigi Avantaggiato

South 8 Technologies

South 8 Technologies Chilldyne

Chilldyne Phoenix Tailings’ senior research scientist Rita Silbernagel explains how mining waste contains useful metals and rare earth elements and can also be used as a place to store carbon dioxide.Emily Waltz

Phoenix Tailings’ senior research scientist Rita Silbernagel explains how mining waste contains useful metals and rare earth elements and can also be used as a place to store carbon dioxide.Emily Waltz

Quidnet Energy brought a wellhead to the 2024 ARPA-E Energy Innovation Summit to demonstrate its geoengineered energy-storage system.Emily Waltz

Quidnet Energy brought a wellhead to the 2024 ARPA-E Energy Innovation Summit to demonstrate its geoengineered energy-storage system.Emily Waltz

Quidnet’s system consists of a surface-level pond, a deep well, an underground reservoir at the end of the well, and a pump system that moves pressurized water from the pond to the underground reservoir and back.Quidnet Energy

Quidnet’s system consists of a surface-level pond, a deep well, an underground reservoir at the end of the well, and a pump system that moves pressurized water from the pond to the underground reservoir and back.Quidnet Energy

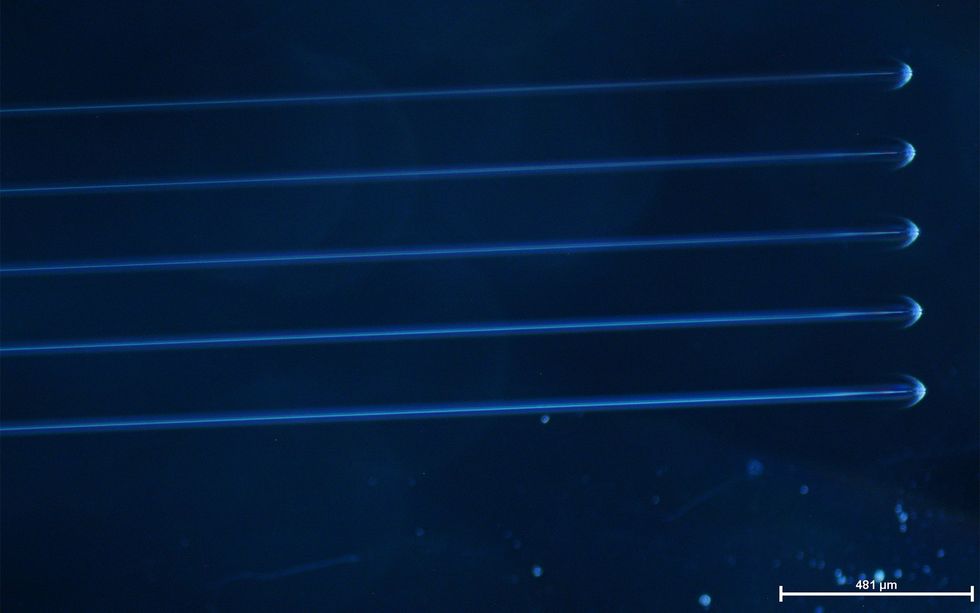

A femtosecond laser welds a small piece of test glass.NREL

A femtosecond laser welds a small piece of test glass.NREL A femtosecond laser creates precision welds between two glass plates.David Young/NREL

A femtosecond laser creates precision welds between two glass plates.David Young/NREL