MIT’s tiny technologies go to Washington

On Nov. 7, a team from the Marble Center for Cancer Nanomedicine at MIT showed a Washington audience several examples of how nanotechnologies developed at the Institute can transform the detection and treatment of cancer and other diseases.

The team was one of 40 innovative groups featured at “American Possibilities: A White House Demo Day.” Technology on view spanned energy, artificial intelligence, climate, and health, highlighting advancements that contribute to building a better future for all Americans.

Participants included President Joe Biden, Biden-Harris administration leaders and White House staff, members of Congress, federal R&D funding agencies, scientists and engineers, academics, students, and science and technology industry innovators. The event holds special significance for MIT as eight years ago, MIT's Computer Science and Artificial Intelligence Laboratory participated in the last iteration of the White House Demo Day under President Barack Obama.

“It was truly inspirational hearing from experts from all across the government, the private sector, and academia touching on so many fields,” said President Biden of the event. “It was a reminder, at least for me, of what I’ve long believed — that America can be defined by a single word... possibilities.”

Launched in 2016, the Marble Center for Cancer Nanomedicine was established at the Koch Institute for Integrative Research at MIT to serve as a hub for miniaturized biomedical technologies, especially those that address grand challenges in cancer detection, treatment, and monitoring. The center convenes Koch Institute faculty members Sangeeta Bhatia, Paula Hammond, Robert Langer, Angela Belcher, Darrell Irvine, and Daniel Anderson to advance nanomedicine, as well as to facilitate collaboration with industry partners, including Alloy Therapeutics, Danaher Corp., Fujifilm, and Sanofi.

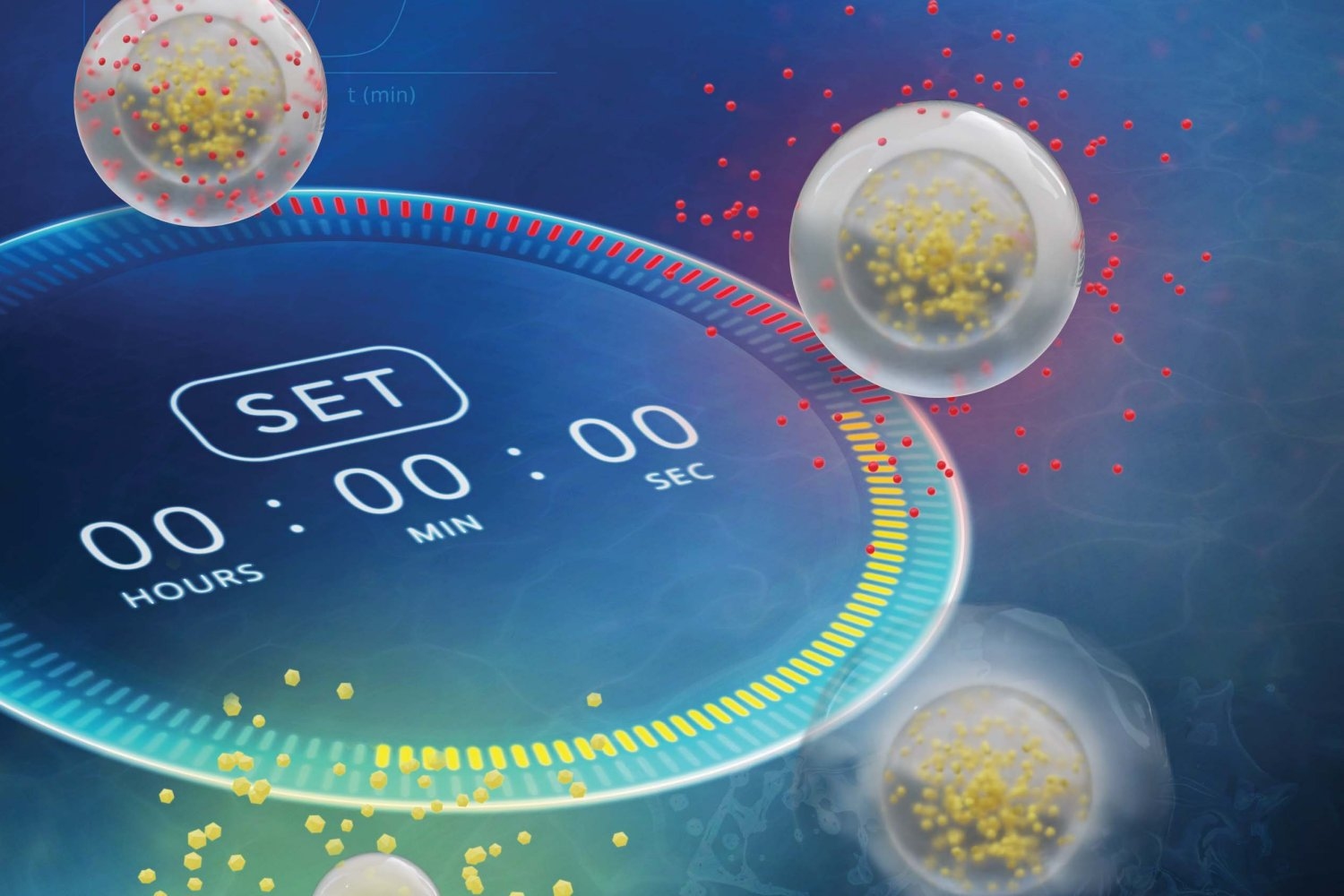

Ana Jaklenec, a principal research scientist at the Koch Institute, highlighted several groundbreaking technologies in vaccines and disease diagnostics and treatment at the event. Jaklenec gave demonstrations from projects from her research group, including novel vaccine formulations capable of releasing a dozen booster doses pulsed over predetermined time points, microneedle vaccine technologies, and nutrient delivery technologies for precise control over microbiome modulation and nutrient absorption.

Jaklenec describes the event as “a wonderful opportunity to meet our government leaders and policymakers and see their passion for curing cancer. But it was especially moving to interact with people representing diverse communities across the United States and hear their excitement for how our technologies could positively impact their communities.”

Jeremy Li, a former MIT postdoc, presented a technology developed in the Belcher laboratory and commercialized by the spinout Cision Vision. The startup is developing a new approach to visualize lymph nodes in real time without any injection or radiation. The shoebox-sized device was also selected as part of Time Magazine’s Best Inventions of 2023 and is currently being used in a dozen hospitals across the United States.

“It was a proud moment for Cision Vision to be part of this event and discuss our recent progress in the field of medical imaging and cancer care,” says Li, who is a co-founder and the CEO of CisionVision. “It was a humbling experience for us to hear directly from patient advocates and cancer survivors at the event. We feel more inspired than ever to bring better solutions for cancer care to patients around the world.”

Other technologies shown at the event included new approaches such as a tortoise-shaped pill designed to enhance the efficacy of oral medicines, a miniature organ-on-a-chip liver device to predict drug toxicity and model liver disease, and a wireless bioelectronic device that provides oxygen for cell therapy applications and for the treatment of chronic disease.

“The feedback from the organizers and the audience at the event has been overwhelmingly positive,” says Tarek Fadel, who led the team’s participation at the event. “Navigating the demonstration space felt like stepping into the future. As a center, we stand poised to engineer transformative tools that will truly make a difference for the future of cancer care.”

Sangeeta Bhatia, the Director of the Marble Center and the John J. and Dorothy Wilson Professor of Health Sciences and Technology and Electrical Engineering and Computer Science, adds: “The showcase of our technologies at the White House Demo Day underscores the transformative impact we aim to achieve in cancer detection and treatment. The event highlights our vision to advance cutting-edge solutions for the benefit of patients and communities worldwide.”