John Joannopoulos receives 2024-2025 Killian Award

John Joannopoulos, an innovator and mentor in the fields of theoretical condensed matter physics and nanophotonics, has been named the recipient of the 2024-2025 James R. Killian Jr. Faculty Achievement Award.

Joannopoulos is the Francis Wright Davis Professor of Physics and director of MIT’s Institute for Soldier Nanotechnologies. He has been a member of the MIT faculty for 50 years.

“Professor Joannopoulos’s profound and lasting impact on the field of theoretical condensed matter physics finds its roots in his pioneering work in harnessing ab initio physics to elucidate the behavior of materials at the atomic level,” states the award citation, which was announced at today’s faculty meeting by Roger White, chair of the Killian Award Selection Committee and professor of philosophy at MIT. “His seminal research in the development of photonic crystals has revolutionized understanding of light-matter interactions, laying the groundwork for transformative advancements in diverse fields ranging from telecommunications to biomedical engineering.”

The award also honors Joannopoulos’ service as a “legendary mentor to generations of students, inspiring them to achieve excellence in science while at the same time facilitating the practical benefit to society through entrepreneurship.”

The Killian Award was established in 1971 to recognize outstanding professional contributions by MIT faculty members. It is the highest honor that the faculty can give to one of its members.

“I have to tell you, it was a complete and utter surprise,” Joannopoulos told MIT News shortly after he received word of the award. “I didn’t expect it at all, and was extremely flattered, honored, and moved by it, frankly.”

Joannopoulous has spent his entire professional career at MIT. He came to the Institute in 1974, directly after receiving his PhD in physics at the University of California at Berkeley, where he also earned his bachelor’s degree. Starting out as an assistant professor in MIT’s Department of Physics, he quickly set up a research program focused on theoretical condensed matter physics.

Over the first half of his MIT career, Joannopoulos worked to elucidate the fundamental nature of the electronic, vibrational, and optical structure of crystalline and amorphous bulk solids, their surfaces, interfaces, and defects. He and his students developed numerous theoretical methods to enable tractable and accurate calculations of these complex systems.

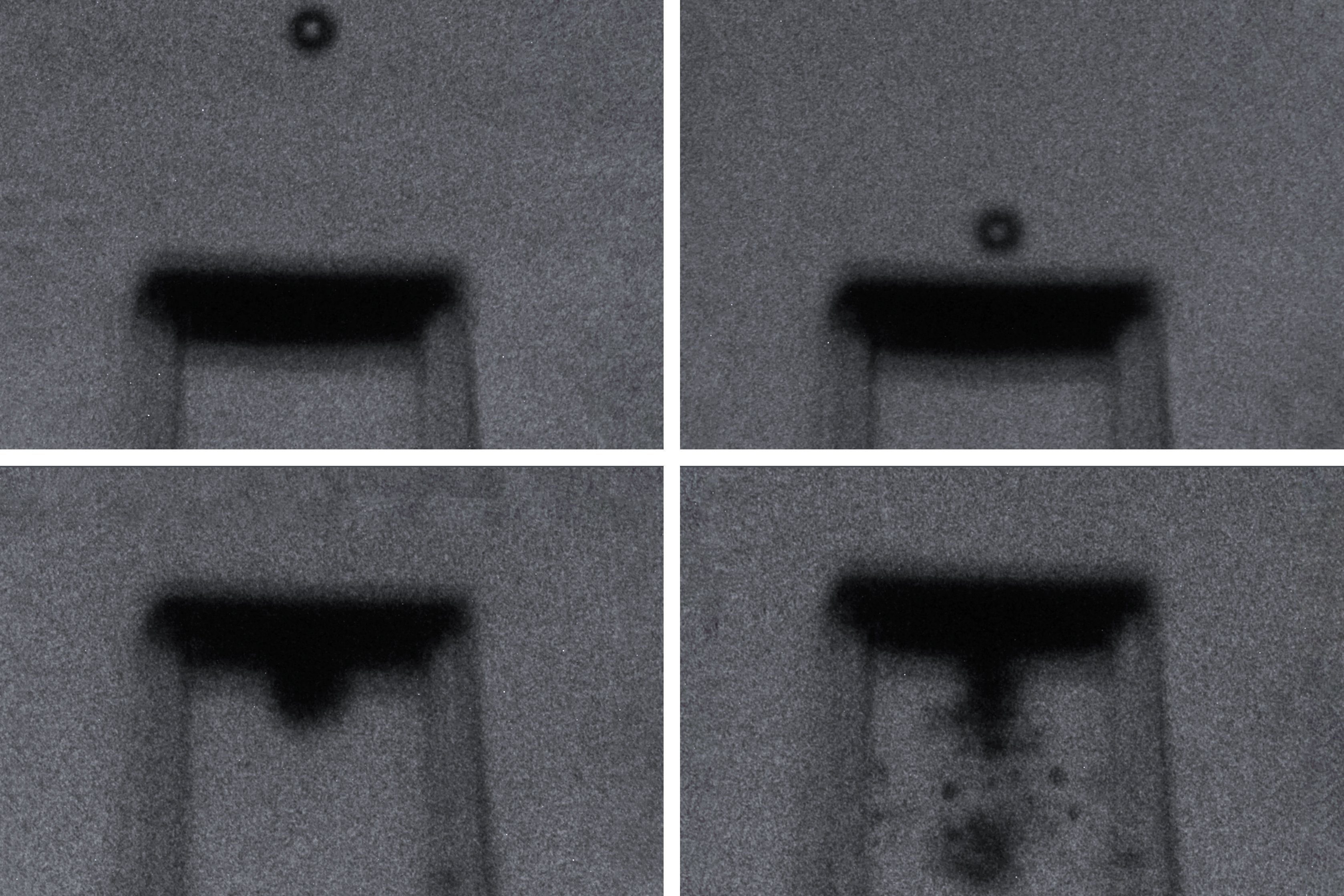

In the 1990s, his work with microscopic material systems expanded to a new class of materials, called photonic crystals — materials that could be engineered at the micro- and nanoscale to manipulate light in ways that impart surprising and exotic optical qualities to the material as a whole.

“I saw that you could create photonic crystals with defects that can affect the properties of photons, in much the same way that defects in a semiconductor affect the properties of electrons,” Joannopoulos says. “So I started working in this area to try and explore what anomalous light phenomena can we discover using this approach?”

Among his various breakthroughs in the field was the realization of a “perfect dielectric mirror” — a multilayered optical device that reflects light from all angles as normal metallic mirrors do, and that can also be tuned to reflect and trap light at specific frequencies. He and his colleagues saw potential for the mirror to be made into a hollow fiber that could serve as a highly effective optical conduit, for use in a wide range of applications. To further advance the technology, he and his colleagues launched a startup, which has since developed the technology into a flexible, fiber-optic “surgical scalpel.”

Throughout his career, Joannopoulos has helped to launch numerous startups and photonics-based technologies.

“His ability to bridge the gap between academia and industry has not only advanced scientific knowledge but also led to the creation of dozens of new companies, thousands of jobs, and groundbreaking products that continue to benefit society to this day,” the award citation states.

In 2006, Joannopoulos accepted the position as director of MIT’s Institute for Soldier Nanotechnologies (ISN), a collaboration between MIT researchers, industry partners, and military defense experts, who seek innovations to protect and enhance soldiers’ survivability in the field. In his role as ISN head, Joannopoulos has worked across MIT, making connections and supporting new projects with researchers specializing in fields far from his own.

“I get a chance to explore and learn fascinating new things,” says Joannopoulos, who is currently overseeing projects related to hyperspectral imaging, smart and responsive fabrics, and nanodrug delivery. “I love that aspect of really getting to understand what people in other fields are doing. And they’re doing great work across many, many different fields.”

Throughout his career at MIT, Joannopoulos has been especially inspired and motivated by his students, many of whom have gone on to found companies, lead top academic and research institutions, and make significant contributions to their respective fields, including one student who was awarded the Nobel Prize in Physics in 1998.

“One’s proudest moments are the successes of one’s students, and in that regard, I’ve been extremely lucky to have had truly exceptional students over the years,” Joannopolous says.

His many contributions to academia and industry have earned Joannopoulos numerous honors and awards, including his election to both the National Academy of Sciences and the American Academy of Arts and Sciences. He is also a fellow of both the American Physical Society and the American Association for the Advancement of Science.

“The Selection Committee is delighted to have this opportunity to honor Professor John Joannopoulos: a visionary scientist, a beloved mentor, a great believer in the goodness of people, and a leader whose contributions to MIT and the broader scientific community are immeasurable,” the award citation concludes.

© Photo: Jose-Luis Olivares, MIT