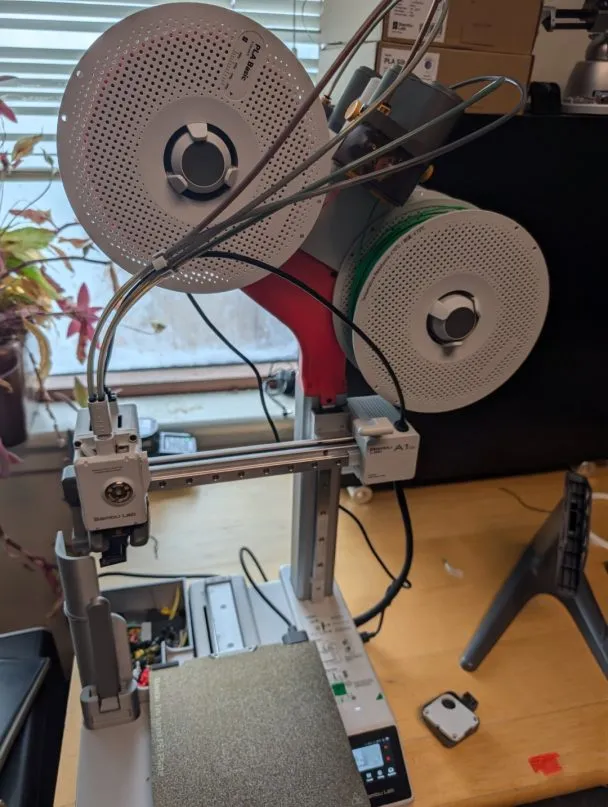

Added a riser to my Bambu A1 Mini and… well, it’s tall now

I needed desk space badly as my desk of hobby/actual work was completely claimed by the A1 Mini and the AMS Lite doohicky sitting next to it. Together they were taking about three horizontal feet of desk space and I didn’t have six inches of desk I could see that wasn’t 3D printer related or not easily accessible.

The windows in the background need replaced, not cleaned (seal broken) which was supposed to have been done months ago – that’s water damage.

I checked the options for compacting the printer and they were wall mount, which was rated “probably the best option” by several people I don’t know, and adding a riser to place the AMS directly over the A1 Mini.

As I don’t have a wall behind the unit (it’s a window) I decided to go ahead and try printing up this riser from here by Spar-Fuchs24.de.

Before I go too far into this story I’ll mention I’ve run two perfect prints and my table does not appear to be shaking around as much, but this may be hopeful thinking.

The print lasted somewhere in the neighborhood of 4 hours – I was out of the office, looked in on Bambu Studio, and there was a printed riser just hanging out living its best life. I got into work today and that was no longer the case – at some point after printing it decided it was going to detach from the plate and make a run for it.

No damage noted I set about removing the printed supports and installing it on the machine. It’s pretty evident what you need to do – remove a top of pole screw, when you remove said screw the top comes off, there’s a plate in there with 3 screws that can be removed with the tools that shipped with the printer, remove that and set the 3 screws aside, and get to screwing them in.

I unloaded all my spools from the AMS because I suspected it was going to be a pain to mount with the spools on, and proceeded to mount it with no real issues. The tubing looked like it was not going to work any more as it was now pretty darn high, but worked fine.

Loaded up, two perfect prints in and with about two feet of additional desk space I’m enjoying it.

I’ll update if I end up with any sub par prints in the next bit, but the added weight seems to have caused the unit to travel less.

Oh yeah, while I cannot find this at the time I’m writing this I ran across a video yesterday while looking for a solution that said that the main problem with this was not being able to access spools 3 & 4 easily. The unit with spools weighs something like 2 fat guinea pigs, just turn the unit if this is a concern.

Added a riser to my Bambu A1 Mini and… well, it’s tall now by Paul E King first appeared on Pocketables.